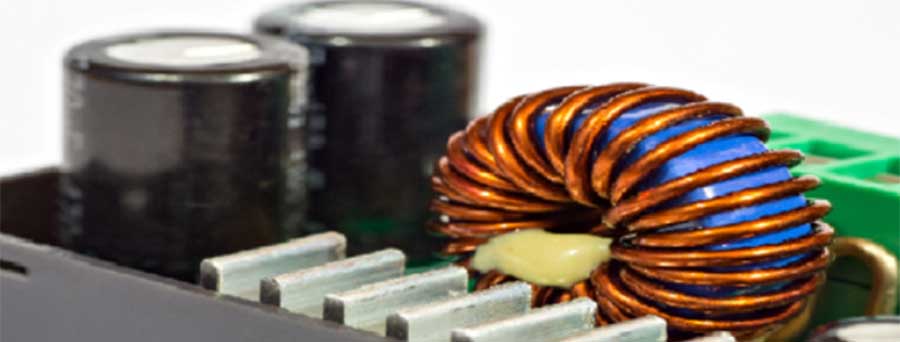

Coil winding is the most important part of making a toroidal transformer because the coil determines the electrical characteristics of the transformer. Here are some of the reasons why custom coil winding is crucial to the performance of a toroidal transformer:

- Inductance: The number of turns and the wire gauge of the coil determine the inductance of the transformer, which is a measure of its ability to store electrical energy. The inductance of the transformer is a key factor in determining its performance, especially in applications that require a specific level of inductance.

- Efficiency: The quality of the winding, including the tightness and consistency of the wire, affects the efficiency of the transformer. Inconsistent or loose windings can result in electrical losses, reducing the overall efficiency of the transformer.

- Magnetic core utilization: The winding also affects the utilization of the magnetic core, which is the heart of the transformer. The winding must be carefully designed to take full advantage of the core’s magnetic properties to maximize the transformer’s performance.

- Current handling capacity: The wire gauge and number of turns also determine the current-handling capacity of the transformer, which is important in applications that require the transfer of high currents.

- Heat dissipation: The winding also affects the ability of the transformer to dissipate heat, which is important in high-power applications. Poorly wound transformers can overheat, reducing their lifespan and performance.

Here are the top reasons to avoid DIY toroid coil winding:

Safety: Winding a toroidal coil involves handling wire and a sharp-edged core, which increases the risk of cuts or other injuries.

Safety: Winding a toroidal coil involves handling wire and a sharp-edged core, which increases the risk of cuts or other injuries.- Accuracy: Without proper equipment, it can be challenging to achieve the desired specifications, such as the number of turns and the inductance, which can result in coils with inconsistent performance.

- Time-consuming: DIY winding can be slow and labor-intensive, especially if the desired specifications are complex or a large number of coils are needed.

- Quality control: Maintaining consistent quality is difficult in DIY winding because keeping the wire tight and secure can be challenging, especially for larger coils.

- Limited capabilities: DIY winding can be challenging, especially for larger coils or those with complex specifications, limiting the types of coils that can be produced.

- Cost: DIY winding may seem like a cost-effective option, but it can be expensive in terms of the time and materials required to produce a high-quality toroidal coil.

- Consistency: Without proper equipment and training, producing consistent and reliable coils can be difficult.

Custom Coil Winding

Given these limitations, DIY custom toroidal coil winding may not be the best for high-volume or complex winding applications. Using a professional winding service or purchasing pre-wound toroidal coils may be more cost-effective and efficient.