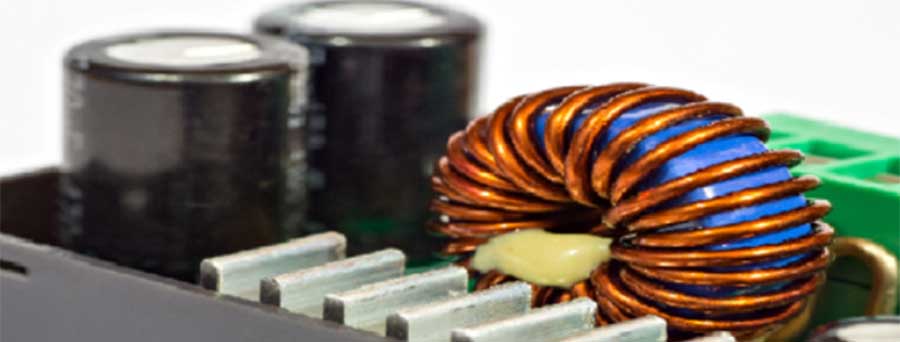

Toroids are commonly used transformers found in a wide berth of electronic devices. They allow electronics to run more efficiently, effectively, and quietly. They also allow electronics designers to minimize designs and create a smaller, more appealing package. Although there are many benefits to using toroids over other similar transformers, a regular toroid is not always the way to go. This is when other options may be more suitable, such as an unencapsulated toroidal transformer.

In short, an encapsulated transformer encloses the winding in an epoxy or similar material. The epoxy coating is a protective barrier that keeps out dust and moisture. The most common uses of this device include the following:

In short, an encapsulated transformer encloses the winding in an epoxy or similar material. The epoxy coating is a protective barrier that keeps out dust and moisture. The most common uses of this device include the following:

- Marine and outdoor equipment

- Portable devices

- Automotive electronics

- Medical equipment

- Industrial environments

What are the characteristics of encapsulated transfers with custom transformer winding? There are many benefits to having an encapsulated transformer with custom winding. An encapsulated transformer offers unparalleled environmental protection compared to a traditional toroid. Enhancing environmental protection can reach ratings up to IP65 or higher (complete protection from dust and low-pressure water jets).

Encapsulated Toroidal Transformers

An enclosed toroid has improved thermal management compared to the non-coated version. This means that the encapsulated materials do a great job of controlling and managing operating temperatures. Lastly, an encapsulated toroid with transformer winding is ideal when EMI is a big problem. Compared to a similarly powered IE core, a regular toroid reduces EMI up to 50%. Encapsulating the toroid will further increase the reduction in EMI.

Related Reading

- Toroid in Audio Systems

When compared to all other transformers, toroids offer the best noise performance.

- B Field Confinement

- Getting the Right Toroids