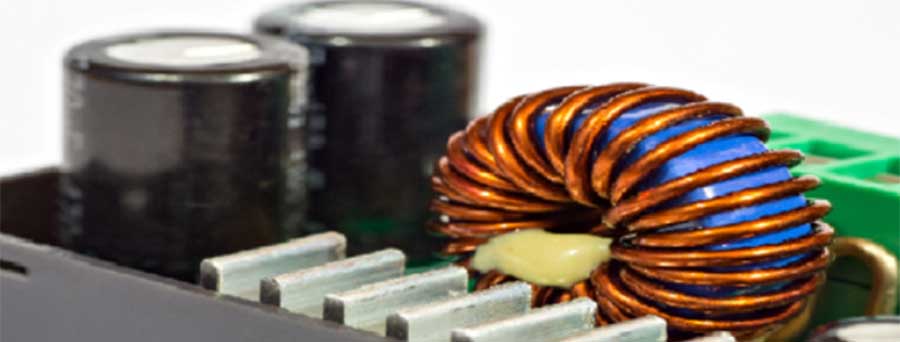

An encapsulated transformer is an electrical transformer in which the windings and core are completely sealed within a material, typically resin. This encapsulation process covers and protects the internal components of the transformer, isolating them from external environmental factors like moisture, dust, and other contaminants. The encapsulating material also provides additional electrical insulation. Encapsulated transformers are commonly used in various applications where protection from environmental factors is essential.

When is the right time for encapsulated transformers?

- Harsh Environmental Conditions: In areas with high humidity, dust, salt, corrosive substances, or other contaminants that could damage a conventional transformer.

- Outdoor Applications: For installations where the transformer will be exposed to weather elements, encapsulated transformers offer better protection against moisture and temperature variations.

- Compact Spaces or Limited Ventilation: Encapsulated transformers, due to their design, are suitable for use in confined spaces where airflow is restricted, as they can manage heat dissipation effectively.

- Safety-Critical Applications: In settings like hospitals, schools, or public buildings where safety is paramount, the additional insulation and protection from the encapsulation minimizes electrical hazards.

- Vibration and Noise Sensitive Areas: Encapsulated transformers are preferred in environments where minimal operational noise and vibration are crucial, such as in audio/visual recording studios or laboratory settings.

Every Job is Different

Encapsulation can be done on all transformers, but each transformer requires a different approach to the process. For instance, a toroid and a step-down/step-up transformer get encapsulated based on their design and application. In other words, encapsulating a transformer differs for each type of transformer and its design and application. Other important factors that figure into the encapsulation process include:

Encapsulation can be done on all transformers, but each transformer requires a different approach to the process. For instance, a toroid and a step-down/step-up transformer get encapsulated based on their design and application. In other words, encapsulating a transformer differs for each type of transformer and its design and application. Other important factors that figure into the encapsulation process include:

- Type of Transformer

- Size & Rating

- Encapsulation material

- Thermal Management

- Safety & Compliance Standards

Toroidal Transformers & Encapsulation Materials

As mentioned above, the material choice for transformer encapsulation differs for each job. For toroidal transformers, the choice of encapsulating material depends on the specific application and environmental conditions they will be subjected to. However, among the materials listed, the following are commonly used for toroids:

- Epoxy Resin: Ideal for high-performance toroidal transformers due to its superior electrical insulation, mechanical strength, and environmental resistance. It’s suitable for applications requiring durability and reliability.

- Silicone Resin: Used for toroidal transformers in high-temperature environments or applications where thermal expansion is a factor. Its flexibility and heat resistance make it a good choice for demanding applications.

- Polyurethane Resin: A cost-effective option for toroids that require good electrical properties and moisture resistance. It’s used in general-purpose applications where extreme environmental conditions are not a concern.

- Polyester Resin: Suitable for standard toroidal transformers in applications where a balance of performance, cost, and moderate environmental protection is needed.

Encapsulated transformers should be left to professionals who pick materials correctly. Ideally, you’ll partner with Torelco: We are highly skilled in custom coil winding and constructing encapsulating transformers. For more information on the encapsulation process or questions about your next project, please call our team today.