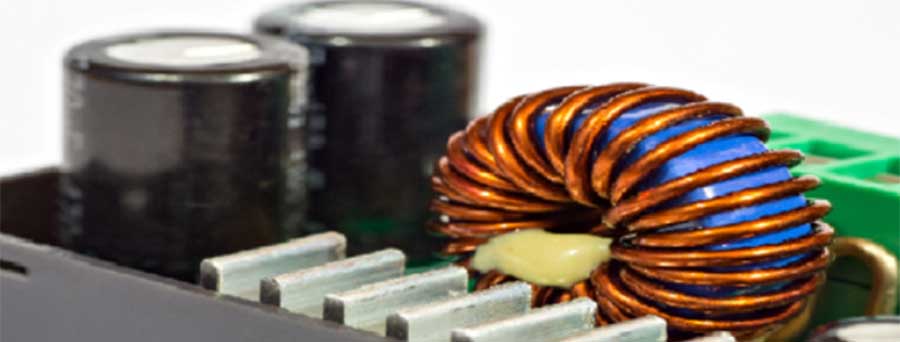

The toroid’s circular shape is what primary makes it such an efficient transformer.

Materials that are magnetized get divided into two classifications: hard and soft. Hard magnets are frequently called permanent magnets because their magnetism is permanently retained through specific manufacturing processes. All hard magnetics have a fixed point on the hysteresis (B-H) curve. A soft core is considered a soft magnet material. The soft materials are magnetically biased when wound with a current-carrying wire. Soft materials are usually driven cyclically along the path of B-H curves. This function makes them inductors and transformers that are usable. Softcore is used to fulfill a wide array of electrical applications.

Considering different options exist for soft magnetic cores, how does one being to know which to use for specific applications? Unfortunately, there is not a general answer to this question, and as such, selection always depends on the needs of an application and its frequencies. Material selection is also subject to tradeoffs. Our team helps you to work through your application requirements to ensure you are getting the right bobbin or toroid transformer.

To make determinations for soft core materials, individuals must know:

1. Application

2. Design parameters

3. Shape

4. Dimension

5. Permeability

6. Magnetic strength

Once hard or soft materials are picked, we then move on to custom coil winding. Call for more information.

Toroids:

- Horizontal Toroid Mounts Installation and Use

Attaching toroids to mounts with mechanical or adhesive means is possible. Horizontal mounting offers low profiles and low center of gravity for applications that experience frequent vibrations and shocks.

- Learning more about Toroidal Transformer Winding And Toroids

- Encapsulated Transformers

- Benefits of Different Cross-Section Shapes

- Warnings and Cautions when using Ferrite Cores