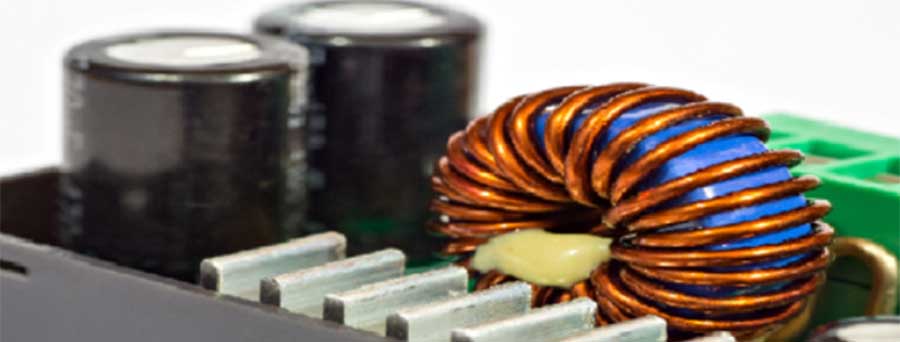

Toroidal transformers are unseen heroes of modern electronic devices. All electronics need help when turning on and off. Traditionally, this was done with EI transformer cores, but modern technology has created better cores under most circumstances. Toroidal transformers are not the right choice for all devices and applications; however, those applications are few and far between. For instance, toroids are not particularly well suited for multi-phase systems and inrush currents.

The applications of toroids are far-reaching, which is why they are used within many vital systems. The medical industry dramatically relies on toroidal transformers and custom coil winding. Toroids are well equipped for critical equipment that needs to function correctly every time it is used. When personal electronics fail, it often results in a minor inconvenience, which is not the case when a piece of medical equipment does not work.

Why does the medical industry heavily rely on coil winding and toroids?

Toroids, when compared to EI cores, offer noiseless operations. Quiet functioning is essential when operating near other machinery, which is often the case with medical equipment.

Coil winding creates low leakage currents that ensure smooth turn-on and off functions. Even the smallest of issues can cause detrimental outcomes. Much of the modern medical equipment used is small in size, and toroids allow designers to fit small toroids into existing designs.

Because toroids are small, they do not add significant weight to the electronic device. Lightweight devices are portable and great for traveling doctors and personal use.