Have you ever encountered issues when customizing a circuit board’s coil windings? If the answer’s a resounding yes, you’re in good company. Today, we will focus on “Understanding Inductance Variations in Toroid Coils: A Key to Custom Coil Winding”. So, buckle up for a whirlwind tour of this crucial aspect of electrical engineering.

Understanding Inductance Variations in Toroid Coils: A Key to Custom Coil Winding

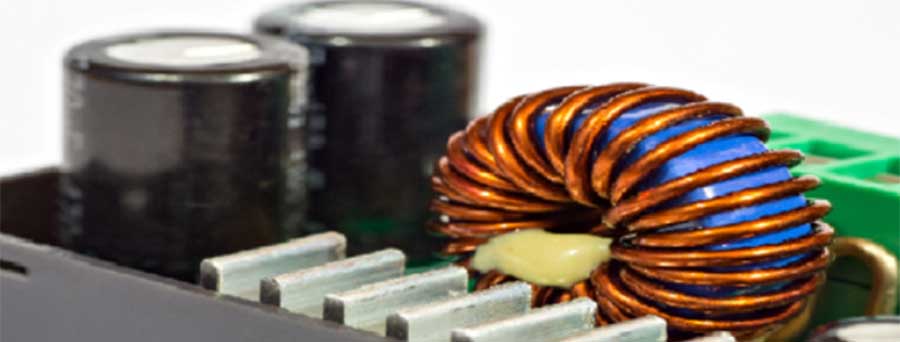

Let’s cut to the chase. What are toroid coils, and what’s the big deal with inductance? Toroid coils, the doughnut-shaped transformers, are a common sight in electronic devices. Their unique structure offers lower magnetic leakage and greater efficiency, making them a top pick for many applications. Now, here’s the kicker – their inductance, which measures the extent to which a change in current produces a change in magnetic flux, varies. This variation gives the toroid coil its mojo, allowing you to customize your coil windings.

Let’s cut to the chase. What are toroid coils, and what’s the big deal with inductance? Toroid coils, the doughnut-shaped transformers, are a common sight in electronic devices. Their unique structure offers lower magnetic leakage and greater efficiency, making them a top pick for many applications. Now, here’s the kicker – their inductance, which measures the extent to which a change in current produces a change in magnetic flux, varies. This variation gives the toroid coil its mojo, allowing you to customize your coil windings.

The Dynamics of Toroid Coils

In the world of toroid coils, it’s all about magnetic flux and electric current. When you change the current flowing through the coil, the magnetic flux reacts, creating inductance. However, this inductance can vary depending on how you wind the coil. The shape, size, and type of material used in the coil will all influence this variation.

The Fine Art of Custom Coil Winding

Custom coil winding is like a conductor orchestrating a symphony – it’s all about harmonizing the elements. With the right tweaks in the winding technique, you can control the inductance of a toroid coil, allowing it to perform optimally for your specific application. So, whether you’re into audio equipment or power supplies, knowing the tricks of custom coil winding can give you the edge.

Unraveling Inductance Variations: How Do They Occur?

How does one navigate these inductance variations? Understanding the underlying factors is key.

- Winding Number: The more turns you make in a coil, the higher its inductance. It’s as simple as that!

- Core Material: The type of material used in the coil core plays a crucial role. Ferrite, for instance, typically offers higher inductance than an air core.

- Winding Technique: It’s not just about quantity, but quality too. How the coil is wound also has a significant impact on inductance.

Tuning in to the Frequencies: Role of Inductance Variations in Audio Equipment

Did you know that inductance variations in toroid coils could make or break the quality of your audio equipment? They are crucial in creating resonant circuits in speakers, amplifiers, and other audio devices. Getting it wrong could lead to poor sound quality and efficiency.

Audio Transformers: Where Inductance Matters

When it comes to audio transformers, inductance variations are a key consideration. The transformer’s inductance affects the frequency response of the audio signal. By manipulating the winding, you can tailor the frequency response to suit your needs.

Powering Up: Inductance Variations in Power Supplies

It’s not just the audio world that benefits from understanding inductance variations. In power supplies, toroid coils maintain stable voltages and filter out noise. The ability to control inductance through custom coil winding is a game-changer here.

Transformers: Powering Efficiency

In transformers, the coils’ inductance helps reduce energy loss and improve efficiency. Variations in inductance can be harnessed to optimize the transformer for specific applications, from industrial equipment to consumer electronics.