How Bondable Wire Coils Improve Reliability and Simplify Integration

You know how frustrating it is when coils fail at the worst possible moment. Imagine a medical device malfunctioning mid-procedure, an automotive sensor intermittently disconnecting, or aerospace equipment failing thousands of feet above ground. When traditional coil connections become loose or deteriorate, your entire product's reliability suffers, potentially leading to serious safety risks. Finding a solution to these integration issues isn't just beneficial—it's essential.

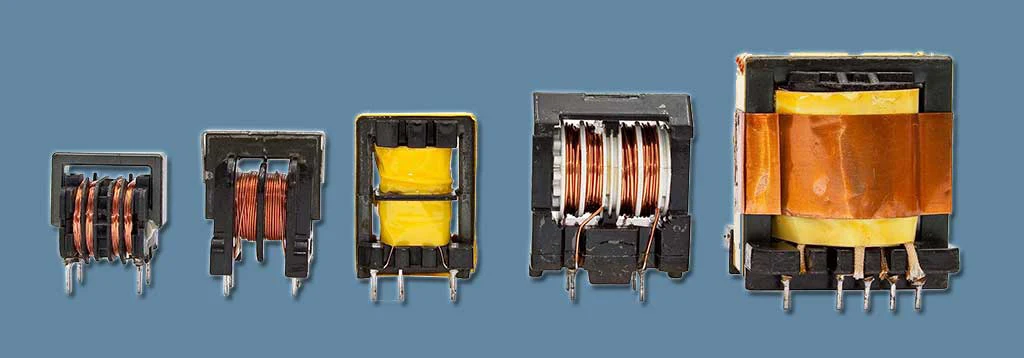

Bondable wire coils directly address these common vulnerabilities by forming secure, direct bonds to PCBs or substrates. Unlike conventional coils with multiple solder points or mechanical attachments prone to failure, bondable wire coils seamlessly integrate into your circuit boards. The outcome is dramatically improved reliability, minimal downtime, and streamlined integration.

Why Do Traditional Coils Often Fail or Disconnect?

Numerous vulnerabilities can develop when traditional coils are mounted on printed circuit boards (PCBs). Coils attached through mechanical fasteners, solder pins, or plastic bobbins often endure stress from vibrations, temperature variations, and regular operational wear. Over time, these stresses degrade the coil connections, increasing the risk of intermittent or total failure. This issue is especially critical in sensitive industries like automotive or medical, where reliability directly correlates with safety.

Typical coil failures involve loose connections from vibrations, deteriorating solder joints under heat and stress, and intermittent signal or power loss due to unstable contacts. Reliable and stable coil integration is essential for consistent performance and customer trust.

How Bondable Wire Coils Strengthen Integration and Reliability

Bondable wire coils significantly reduce mechanical and electrical vulnerabilities by adhering directly to the PCB or substrate. By eliminating intermediate attachment points, bondable coils form secure, direct bonds, providing mechanical stability and electrical continuity.

The practical improvements include fewer points of failure, ensuring coils remain firmly connected despite vibrations or temperature changes. Direct bonding ensures stable inductance and uninterrupted electrical pathways, which are crucial for precise operations. Enhanced thermal stability due to direct bonding also protects sensitive electronics from overheating, significantly prolonging equipment lifespan.

This simplified and robust integration approach is invaluable in industries such as aerospace, automotive sensors, and medical implants, where reliability directly affects safety and efficiency.

Specific Materials and Features that Enhance Coil Reliability

The reliability of bondable wire coils depends heavily on the quality of materials used. At Torelco, our bondable coils incorporate carefully selected materials designed for specific industry demands, significantly enhancing reliability and overall performance.

We use copper and specialized alloy wires known for robust electrical conductivity and resistance to corrosion, which are ideal for harsh environments in automotive or aerospace settings. Our high-grade insulation materials withstand extreme temperatures, humidity, and chemical exposure, maintaining coil integrity in demanding medical or automotive applications. Furthermore, temperature-resistant adhesives guarantee secure bonding under challenging thermal and mechanical conditions, preserving functionality and reliability.

These intentional and detailed material choices improve the operational longevity of your applications.

Real-World Examples of Enhanced Integration Using Bondable Wire Coils

Bondable wire coils have successfully addressed integration and reliability problems across multiple challenging industries.

- In medical devices, manufacturers of precision sensors for pacemakers adopted bondable coils to eliminate coil displacement issues. As a result, device failures significantly decreased, ensuring consistent, safe patient outcomes.

- A prominent automotive electronics supplier integrated bondable coils directly onto sensor boards, substantially reducing intermittent faults caused by vibration-induced solder failures. Field returns declined by over 60% within one year, demonstrating the tangible reliability benefits.

- For aerospace components, bondable coils were used in aircraft navigation modules subjected to extreme mechanical and thermal stress. The direct bonding ensured continuous power and signal integrity under demanding flight conditions, drastically improving operational reliability.

These real-world implementations illustrate how bondable wire coils effectively solve industry-specific integration challenges, significantly boosting reliability.

Reliable Integration is Possible Now

Bondable wire coils provide a clear solution to reliability and integration problems inherent in traditional coil designs. Securely bonding directly to PCBs or substrates effectively minimizes mechanical failures, ensures electrical consistency, and simplifies manufacturing processes. If reliability and simplified coil integration are crucial to your applications, contact Torelco today to explore tailored bondable coil solutions designed specifically for your needs.